▌Home > Products > DDR5 SMT Type

DDR5 SMT TYPE

DDR5 provides higher transmission speed and less space than DDR4.

▂▂

DDR DEVELOPMENT

COMPARATION

DDR4 & DDR5

DDR4

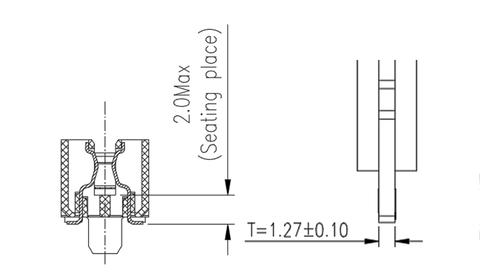

Seating Place

2.4 mm MAX

DIMM Card Thickness

1.4 +/-0.10 mm

Transmission rate

3.2 G

Voltage

1.2 V

★

DDR5

Seating Place

2.0 mm MAX

DIMM Card Thickness

1.27 +/-0.10 mm

Transmission rate

6.4 G

Voltage

1.1 V

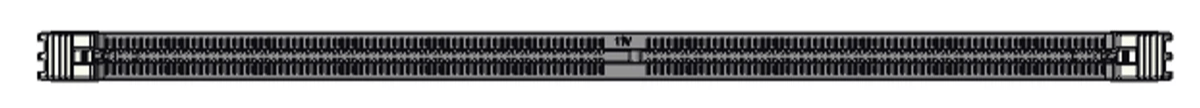

DDR5 TYPE

DDR5 FOR R/LR DIMM

D=3.875

DDR5 FOR UDIMM

D=1.425

DDR5 APPLICATION

DDR5 will be widely used in the following fields as it has the faster

transmission speed:

➊ Personal PC and server

➋ Large data processing center

➌ Artificial intelligence technology and machine learning cloud technology, Internet

➍ lock chain

➎ Virtualization and AR/VR/MR Solutions

➏ Monitoring system

PRODUCT STRUCTURE CHARACTERISTICS

Structure features: The terminal is fixed by injection molding , and then put the molding into the housing body, to avoid the terminal directly into the housing body cause the deformation. Solved the product in SMT process welding issue .

BEFORE AND AFTER IR

Different processes are used to ensure the flatness of products before and after IR and excellent solder performance, and ensure the stability of solder in SMT process.

SOLDERING STATUS

After Soldering

▂▂

PRODUCT SPECIFICATIONS

MATERIAL

Contacts

Copper alloy, Gold flash or 15 µin min. of gold or 30 µin min. of gold (Contact area), matte tin plating(Solder Area), Nickel plating over all (Underplate)Insulator & Latch

High temperature, thermal plastic (UL94V-0), color option.Boardlock

Stainless steel, Tin plating ,Nickel plating overall (Underplate)ENVIRONMENTAL

Solderability

95% min.Resistance to Soldering Heat

Visual-no damage or discoloration of connector materials Temperature Life, Thermal Shock, Cycling Temperature and HumidityTemperature Rise

30°C max.Mixed Flowing Gas, Thermal Disturbance, Salt SpraySPECIFICATIONS

JEDEC Module Outlines

MO-329JEDEC Socket Outlines

SO-023PACKAGING

TrayELECTRICAL PERFORMANCE

Voltage Rating

29V AC (RMS)/DC CurrentRating

0.75 Amps/pin max.Low Level Contact Resistance (max.)

30 milliohmDielectric Withstanding Voltage

500V AC InsulationResistance (min.)

100 MegohmMECHANICAL PERFORMANCE

Insertion Force

106.8N max.Withdrawal Force

19.77N min.Retention Force

Contact: 300gf min. per pin

Boardlock: 13.3N min.Durability

25 cycles Vibration, Mechanical ShockLatch Overstress Force

3.5kg min. force held for 10s with no damageReseating

No damageLatch Actuation Force

The force to fully actuate the latch open shall be 4.5kgf max. per latchModule Rip Out Force

9.1kgf min. retention force of the module in connector with no damageRetention of Connector to PCB

No lifting of connector from applicable PCBTotal Insertion Force

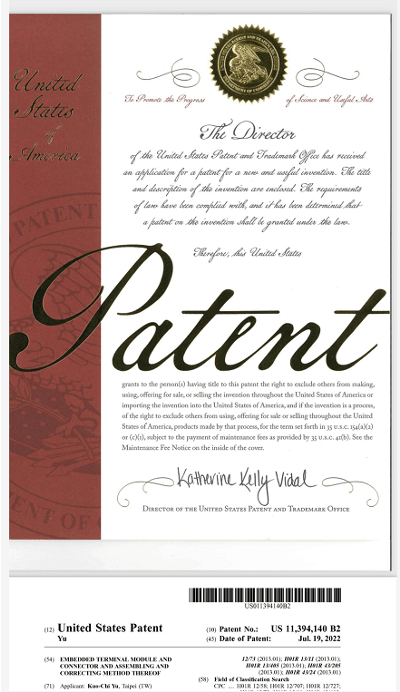

75N maxPATENT CERTIFICATION

USA

▌Home > Products > DDR5 SMT Type

CONTACT US

T. +886-6604-0006

M. trestliu@

VAT. 90480677

SERVICES

- Precision Stamping/Plastic Tooling

- Design and Manufacture

- Metal Part Mass production

- Production & Assembly

- CNC Machining

BF Ltd.

CALIFORNIA

2027 BELOIT AVE, LOS ANGELES, CA90025

TAIPEI

Rm.1, 4F., No.11, Ningxia Rd., Datong Dist., Taipei City 103019, Taiwan